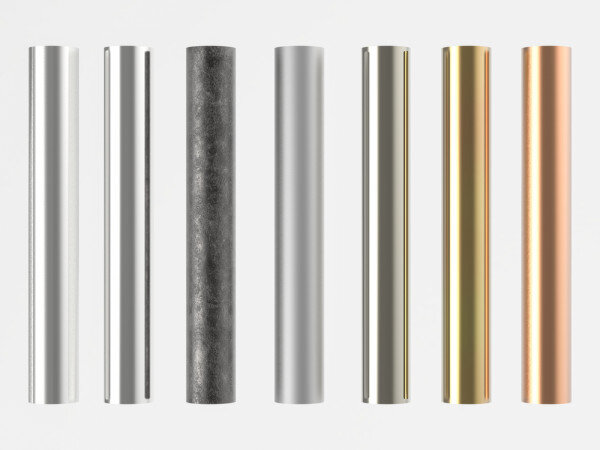

Aluminium is often refined by powder coating or anodising (electrolytic oxidation) to achieve greater resistance to rust and wear. Anodised aluminium has the hardest and most scratch-resistant surface and therefore also provides the best protection against corrosion. Cast aluminium is a lower-quality variant of the metal that makes the manufacturing process particularly cost-effective.

Nickel and chrome tend to be applied as a thin layer to the surface of cast aluminium, aluminium or iron luminaires to protect these less durable metals from rust and signs of use while creating a special appeal. Caution: When cleaning, care must be taken to avoid scratches on the surface, which sooner or later cause material wear and ugly spots. Metal luminaires can be cleaned easily and quickly with a damp cloth with a smooth surface. Nickel is usually matt but often available in chrome, which is usually so shiny that you can see yourself reflected in it.

For centuries, wrought or cast iron has been an essential building block for lights in the rustic-traditional country house style, for example lantern-like outdoor luminaires and pendant lamps with ornate frames and milky glass shades. As it is very weather-resistant, it can remain outdoors all year round without suffering any damage. The only disadvantage, depending on the intended use, is the high weight and the relatively high risk of rust, which is counteracted with paint finishes.

Stainless steel, steel with less than 0.025 % sulphur, and phosphorus look particularly high-quality and are lighter and equally weather-resistant. In addition, stainless steel lights do not rust as quickly. But even if stainless steel is described as 'rust-free' - eventually rust spots will come, although this may take many decades.

Lights made of brass or old brass, alloys of copper, zinc and other metals, look golden, which makes them look particularly elegant. Nevertheless, they are relatively inexpensive. The only disadvantage is that brass needs regular maintenance to prevent deposits of grease and dirt from building up and making the material dull. Many brass lamps, however, are coated with a colourless protective layer of lacquer that is simply wiped off and does not need polishing.

Plastics: Inexpensive and Practical

Plastics are very inexpensive to manufacture and are characterised by very low weight. In processing, they can be bonded much better than metals. All colours are possible without any problems. Many lampshades are made of acrylic glass (PMMA, polymethyl methacrylate), which is often colloquially equated with the brand name Plexiglas.

One of the disadvantages of plastic is that it takes 500 years to decompose; recycling processes are usually not economical enough. Artificially derived from refining petroleum, they age continuously: they are very easy to clean with a suitable care product and a soft cloth, but the wrong cleaning agents and oils can cause ugly spots on the surface that quickly worsen.